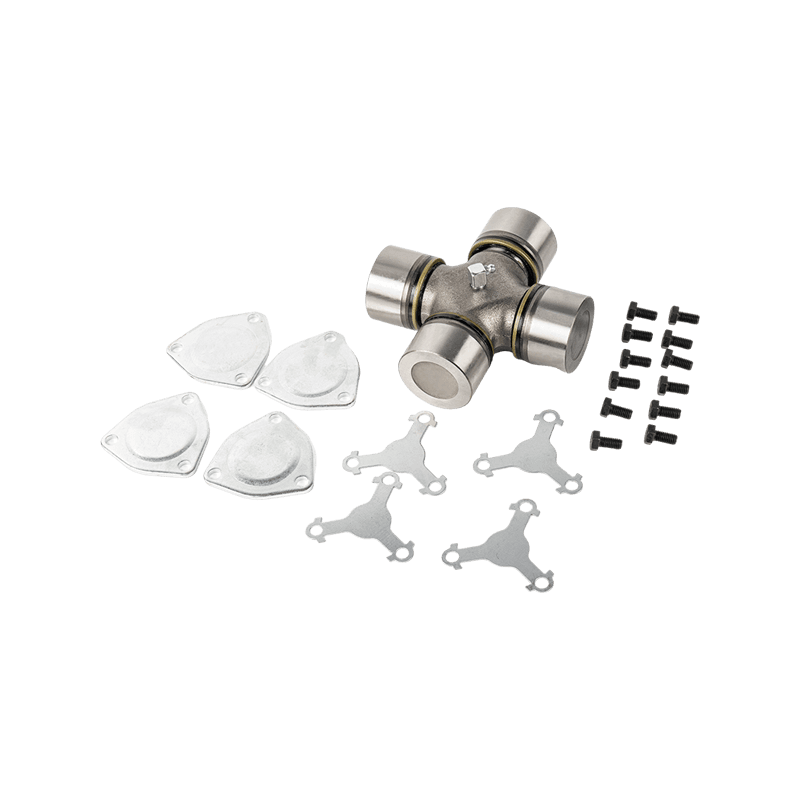

Advantages of TRUCK VEHICLE u-joint

In the complex mechanical structure of TRUCK VEHICLE, u-joint is one of the key components that connect the various parts of the transmission system. Its excellent performance and multifunctional characteristics occupy a pivotal position in the heavy truck industry.

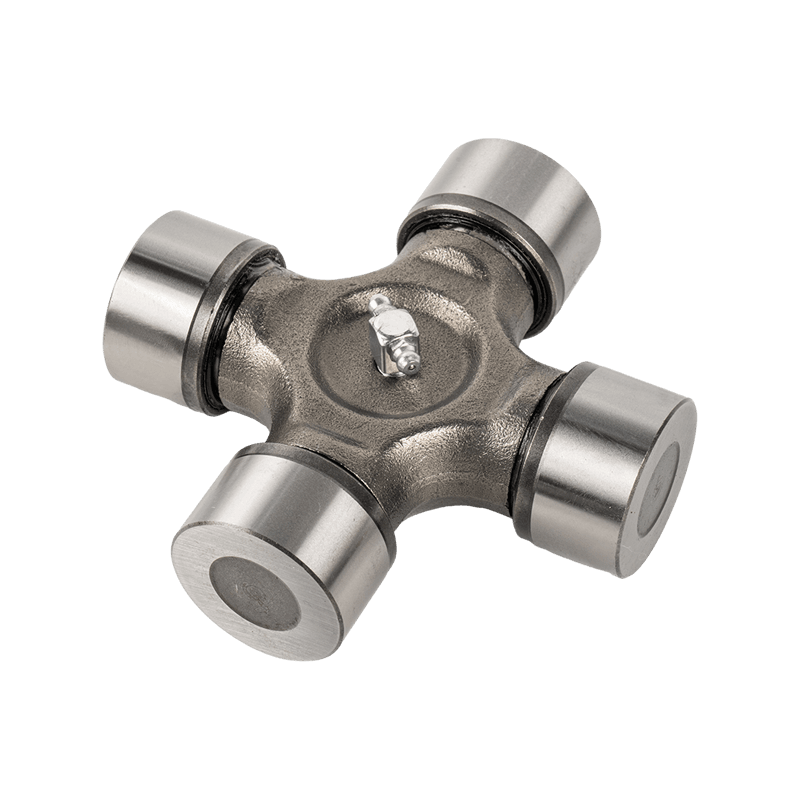

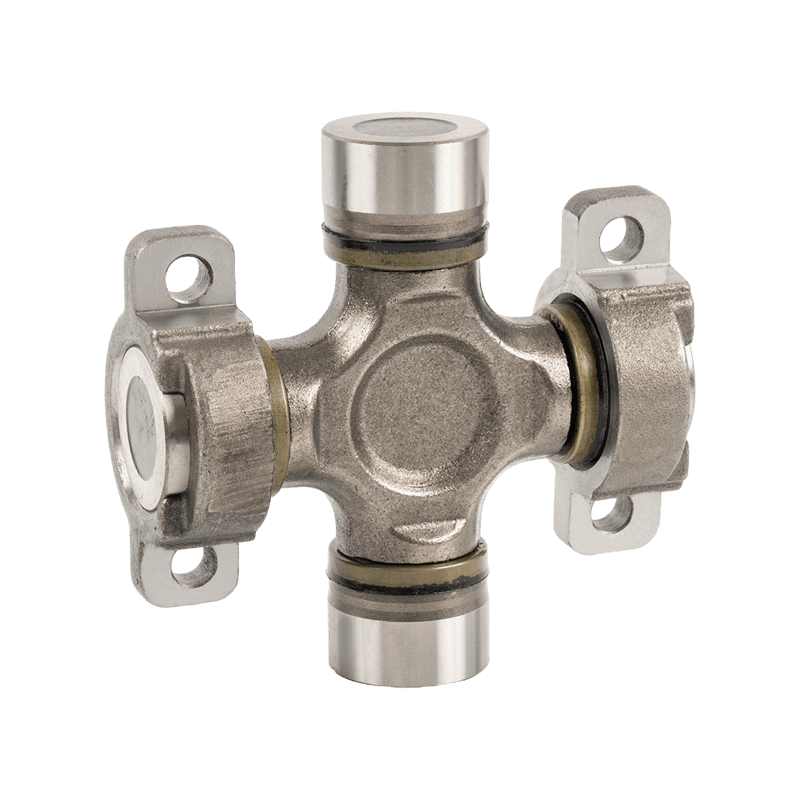

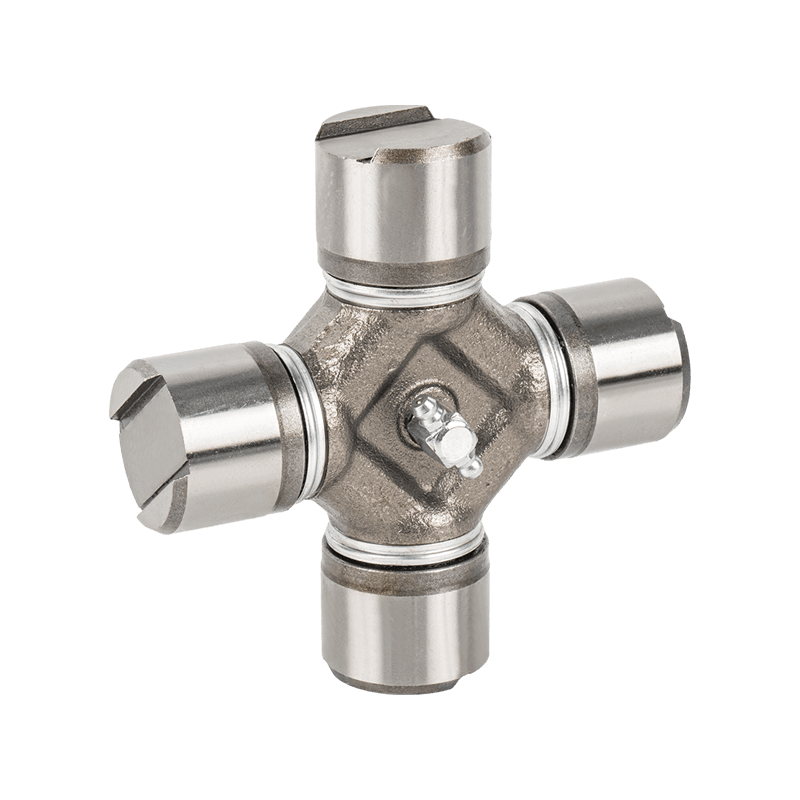

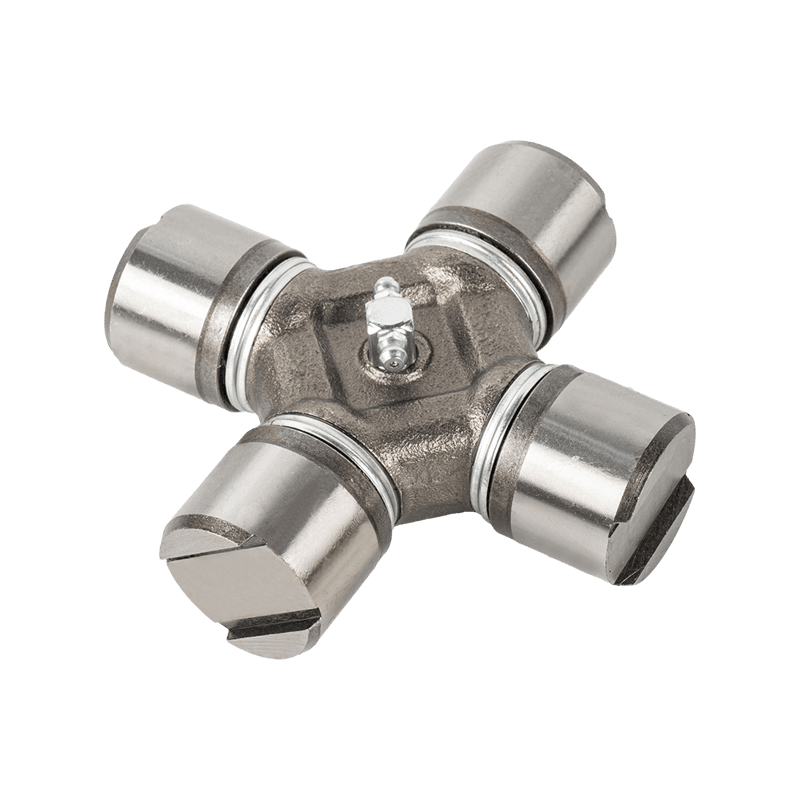

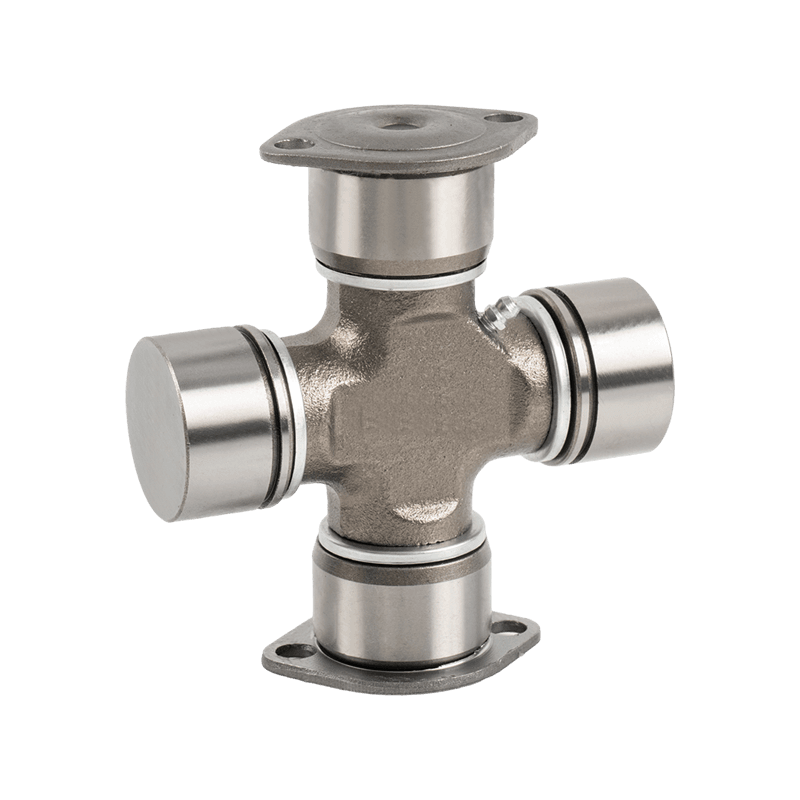

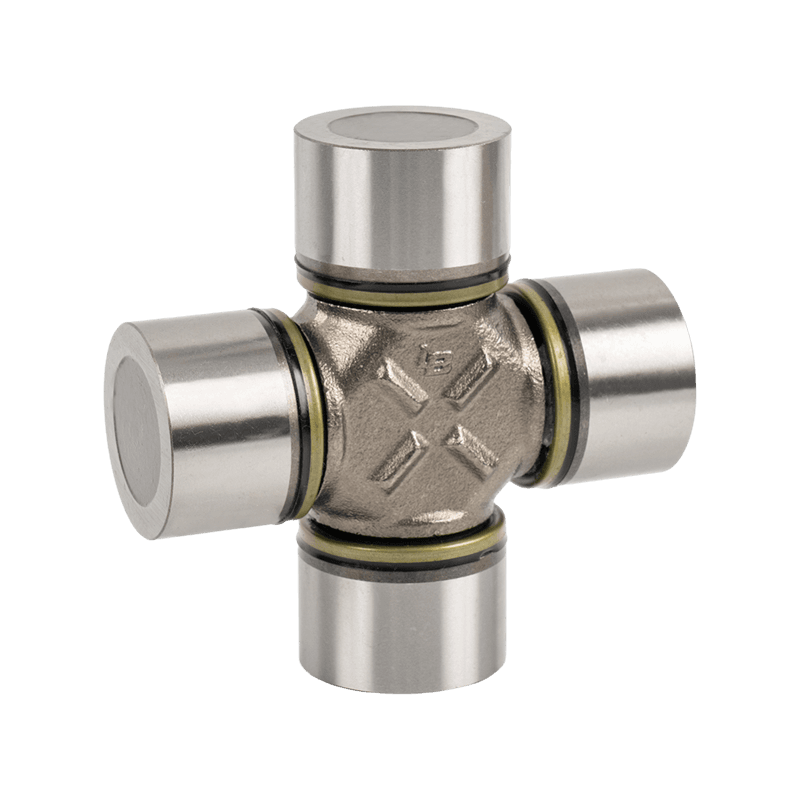

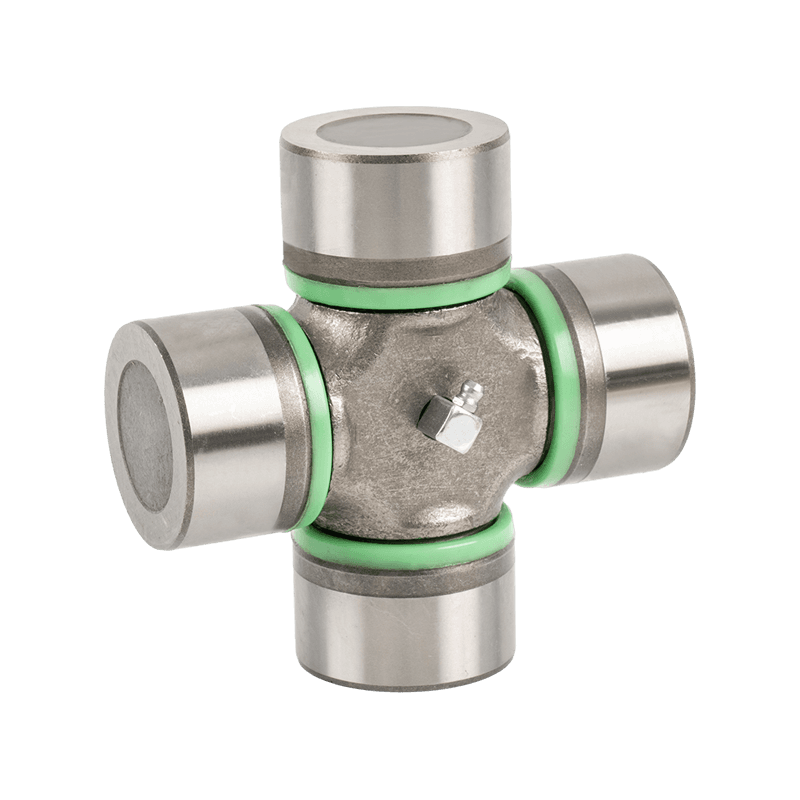

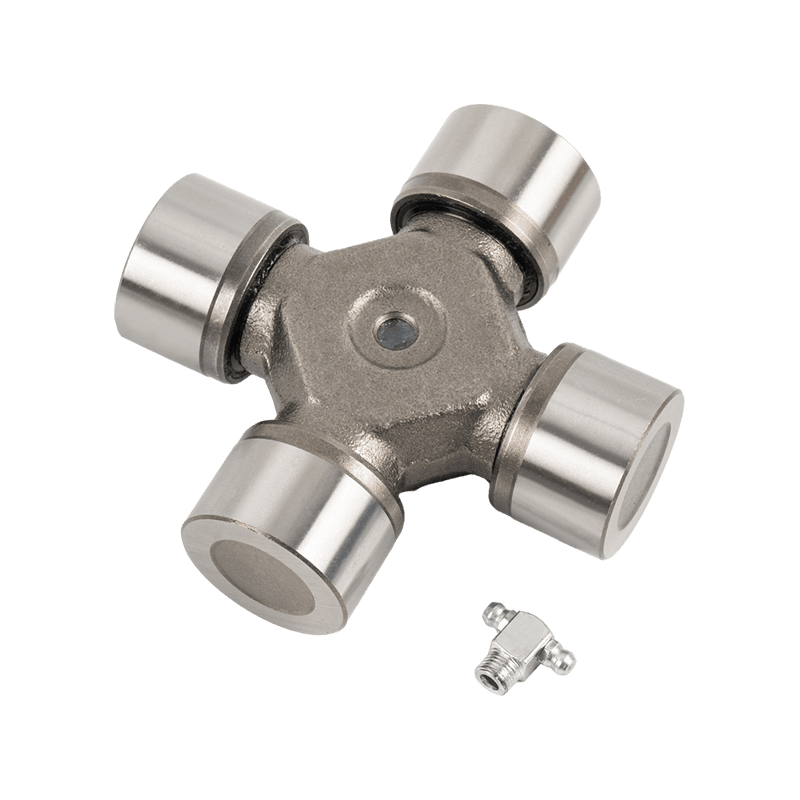

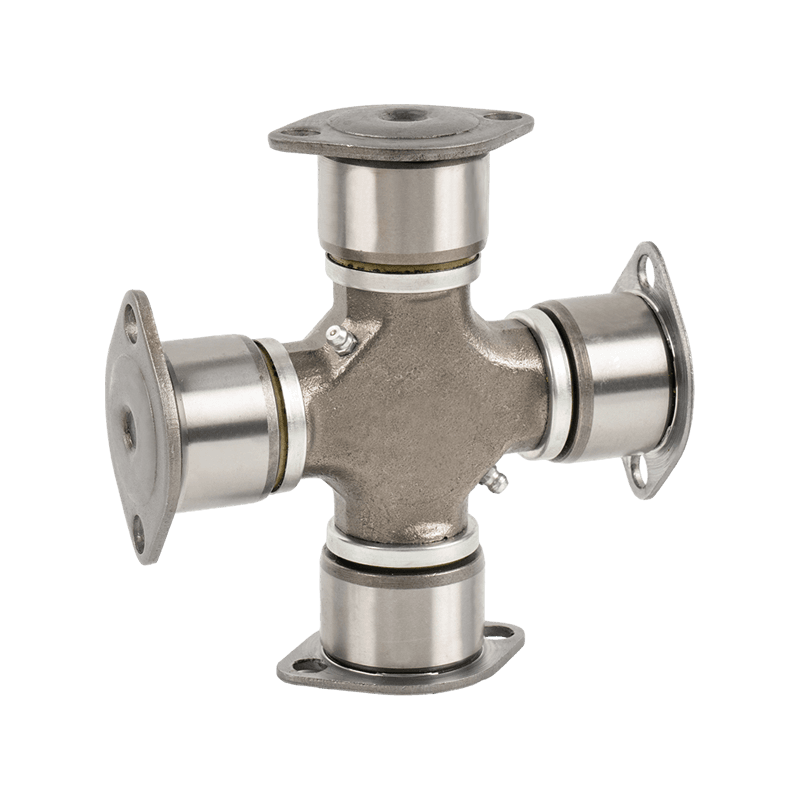

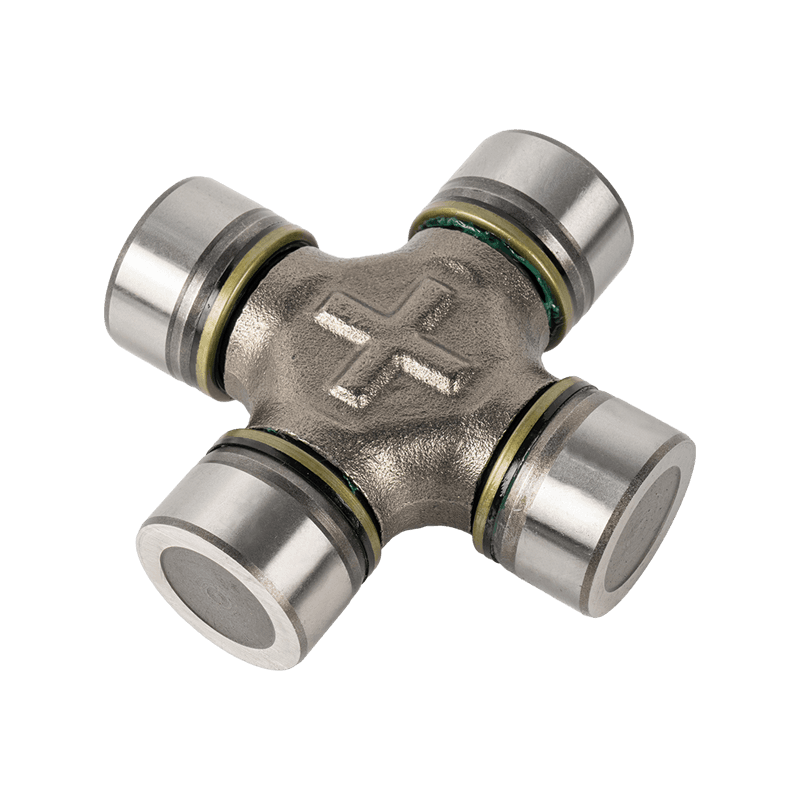

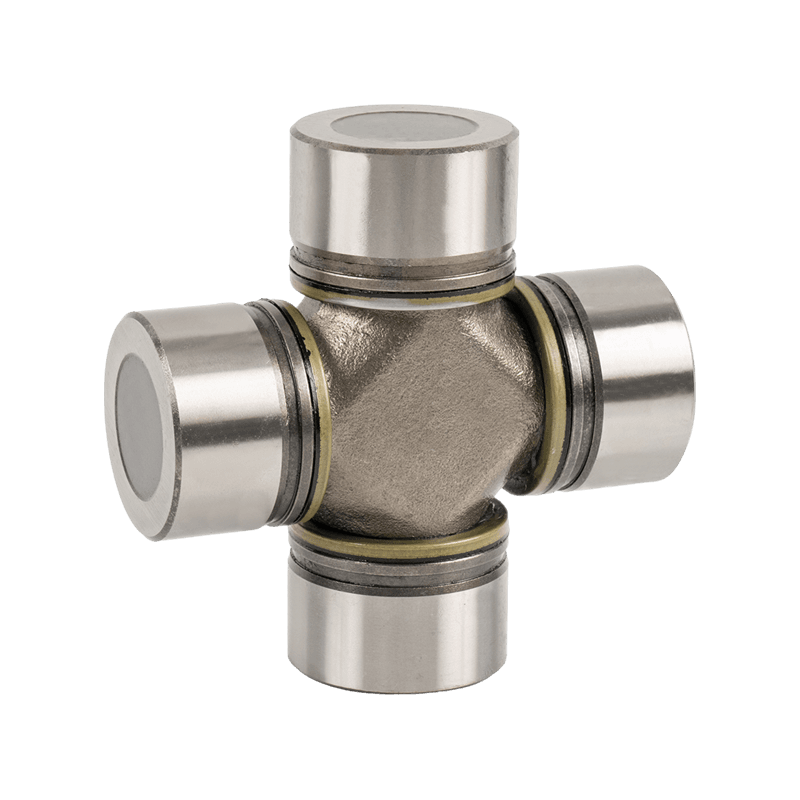

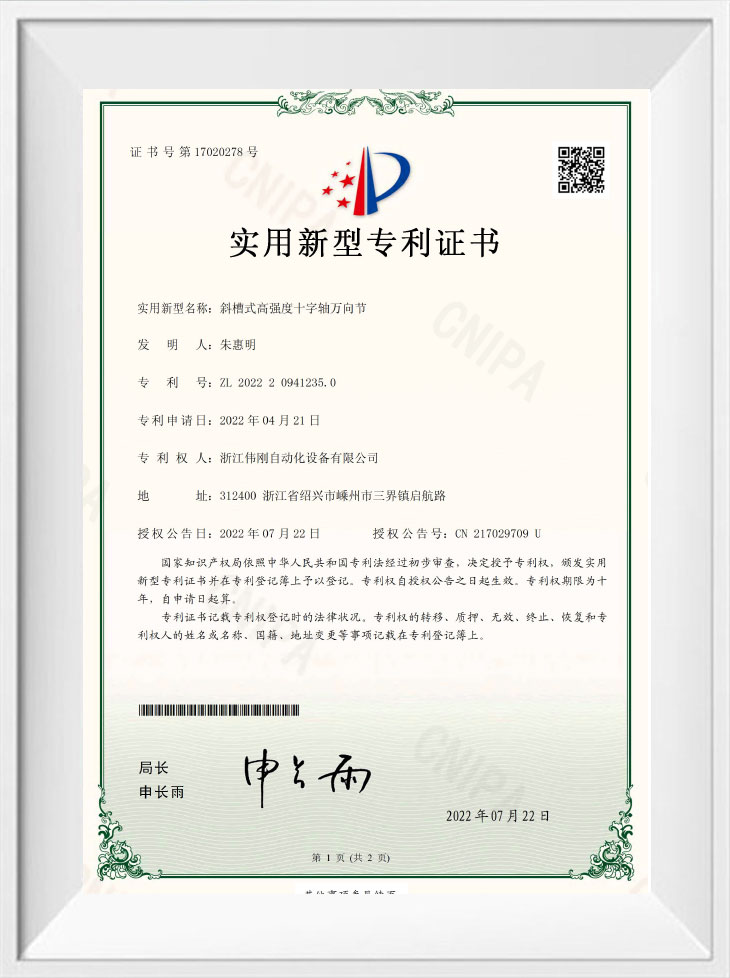

The shape of the u-joint is "U", consisting of two crossed universal joint forks and a cross shaft located between them. This structure allows the connecting shaft to rotate freely on two mutually perpendicular planes, realizing the power transmission of the drive shaft at different angles. The material of the U-joint is usually high-strength alloy steel to ensure that it can withstand huge torque and impact in a high-load, high-speed working environment. The working principle of the U-joint is based on its unique structural design. When two mutually perpendicular drive shafts need to transmit power, the U-joint can allow a certain angle deviation between them. This deviation is achieved by rolling and sliding the cross shaft in the universal joint fork. When the angle of the drive shaft changes, the cross shaft will rotate accordingly while maintaining contact with the universal joint fork, thereby ensuring that the power can be transmitted continuously and smoothly.

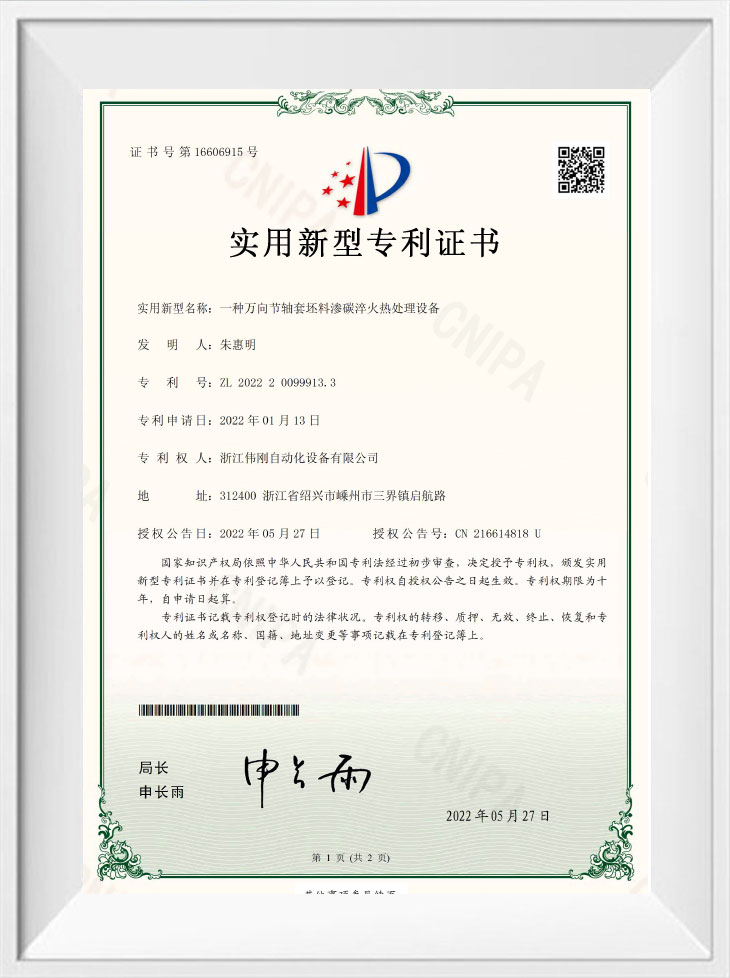

During the driving process of heavy trucks, due to the complex and changeable road conditions, the transmission system often needs to withstand torques of various angles and directions. The application of U-joints allows the drive shaft to flexibly respond to these changes and ensure the continuity and stability of power transmission. This is of great significance for improving the driving smoothness and maneuverability of trucks. Since the U-joint can allow a certain angle deviation between the drive shafts, it can reduce the energy loss caused by angle changes. Its high-precision processing and high-quality material selection also ensure the high efficiency during power transmission. This has a positive effect on improving the fuel economy of trucks and reducing operating costs. The working environment of heavy trucks is harsh, and the transmission system often needs to withstand high loads, high speeds and frequent vibration shocks. The U-joint is made of high-strength alloy steel and has undergone precision processing and heat treatment. It has high wear resistance and fatigue resistance, which enables it to operate stably for a long time in harsh working environments and extend the service life of the transmission system.

In heavy trucks, the stability of the transmission system is directly related to the safety performance of the vehicle. The application of U-shaped joints ensures the stability and reliability of the transmission system under various working conditions, which helps reduce the risk of vehicle loss of control and accidents caused by transmission system failure and improves the overall safety of the vehicle.

How to maintain and service TRUCK VEHICLE u-joint

1. Regular inspection and cleaning

It is recommended to conduct regular inspections of the U-joint every certain mileage (such as 5,000 to 10,000 kilometers) or according to the provisions of the vehicle manual. Check the appearance of the U-joint for signs of cracks, wear or corrosion; check whether the dust cover is intact to prevent dust and moisture from entering; check whether the connecting bolts are loose or damaged. When cleaning, use a clean cloth or compressed air to remove dust and dirt around the U-joint, especially the dust inside the dust cover, to prevent it from affecting the normal operation of the U-joint.

2. Lubrication and grease management

1. Lubrication: An appropriate amount of lubricating grease is required inside the U-joint to reduce friction and wear. According to the recommendations of the vehicle manufacturer, regularly inject an appropriate amount of lubricating grease into the U-joint. Pay attention to selecting lubricating grease that meets the requirements of the vehicle transmission system to ensure that it has good extreme pressure anti-wear, anti-oxidation and anti-rust properties. Check the status of the lubricating grease regularly. If the grease is found to be deteriorated, diluted or contains impurities, it should be replaced with a new lubricating grease in time. When replacing lubricating grease, ensure that the old grease is completely removed and new grease is injected in strict accordance with the prescribed amount.

3. Tightening and adjustment

Check and tighten the connecting bolts between the U-joint and the drive shaft, and use a torque wrench to tighten according to the torque value specified by the manufacturer to ensure that the connection is firm and reliable. According to the vehicle requirements, regularly check and adjust the clearance of the U-joint. Too large or too small a clearance will affect the stability and efficiency of the transmission system. When adjusting the clearance, special tools should be used and the prescribed steps should be followed to avoid damage to the U-joint.

4. Troubleshooting and handling

When abnormal sounds, vibrations, or oil leaks are found in the U-joint, troubleshooting should be carried out in a timely manner. Determine the cause of the fault by checking the appearance, measuring the clearance, checking the lubricating grease, etc. Take appropriate treatment measures according to the results of the troubleshooting. Such as replacing damaged parts, adjusting the clearance, replacing lubricating grease, etc. For faults that cannot be handled by yourself, contact professional maintenance personnel for repair in a timely manner.

The maintenance and care of TRUCK VEHICLE U-JOINT is an important part of ensuring the stable and efficient operation of the heavy-duty truck transmission system. Through regular inspection and cleaning, lubrication and grease management, tightening and adjustment, and troubleshooting and handling, the service life of the U-joint can be effectively extended, and the reliability and safety of the transmission system can be improved. It is also necessary to follow the maintenance and care guidelines of the vehicle manufacturer to ensure the scientific and standardized maintenance and care work. In daily use, drivers and maintenance personnel should pay close attention to the status of the U-joint, and promptly discover and deal with potential problems to ensure the normal operation and driving safety of heavy-duty trucks.